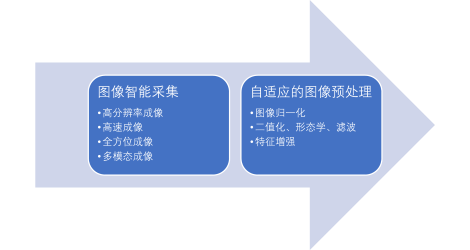

? Image processing: It involves obtaining a series of attribute indicators related to digital images through techniques such as image compression, image enhancement, and frequency domain analysis of image signals, facilitating targeted image quality enhancement or preliminary feature extraction. Image processing algorithms are commonly used as key pre-processing and post-processing techniques for computer vision, machine learning, deep learning, and other relevant tasks.

? Computer vision: It is a technology that simulates the human visual mechanism to acquire signals based on optical sensing technology. By enabling computers to imitate human processing of these optical signals, it allows them to understand scenes, objects, and various target patterns in the real world through visual signals such as images and videos. It is used for production quality inspection and analysis in most industrial fields.

? Based on early machine learning algorithms, high-accuracy defect detection and classification in the field of industrial production have been achieved under the constraints of application scenarios and limited data, serving as an effective auxiliary means for industry production quality control.

? The analysis results of early machine learning on production data are conducive to the collection and organization of industry data sets, laying a data foundation for the subsequent expansion of deep learning-based technology in industry applications.

? With the continuous accumulation and expansion of industry product data, deep learning research findings are first applied to intelligent quality inspection in industrial production, which not only improves the accuracy of defect detection and classification but also greatly enhances robustness.

? Defect detection for products with regular textures has been achieved using autoencoder models, utilizing a large set of easily collected positive samples and employing self-supervised learning algorithms to achieve precise segmentation of defects.

? Generative models have been employed to create samples of some rare defects, which to some extent alleviates the issue of unbalanced defect samples.

? Driven by the rapid development of large models, there is an attempt to leverage prior knowledge and prompt engineering based on large language models, utilizing multimodal learning to achieve rapid model transferability in application fields with little data. The usage patterns of intelligent quality inspection in industrial production are also extended, greatly enhancing users' sensory experience.

? Industrial production quality is closely related to factors such as the quality of raw materials, storage environment, and the condition of production equipment, and the parameters associated with these factors are multidimensional and complex. Therefore, based on big data analysis technologies, data cleaning is carried out starting with data pre-processing algorithms, followed by the use of deep learning models capable of handling time series data to analyze the cleaned data. The models are trained under the set target tasks, ultimately achieving functionalities such as product quality prediction, parameter correlation analysis, comprehensive quality evaluation of the production process, equipment status monitoring, and intelligent equipment maintenance.